PTK Vacuum Chucks is an intelligent Chuck commonly used in the cutting and machining of non-magnetic materials, such as grinding machines, CNC precision machining machines, and CNC equipment. It utilizes compressed air to strongly adsorb workpieces. (Non-magnetic materials include: plastics, stainless steel, copper, brass, aluminum, acrylic sheets, glass, etc.). The equipment is mainly composed of a Chuck,Chuck connector,Chuck base, and a vacuum generator. It can be selected and assembled according to different working environments and workpiece requirements.

The advantages of the PTK vacuum chuck are high stability, strong suction force, and long service life, significantly improving production efficiency and product quality. The device also features simplicity in structure, easy installation, and low maintenance costs, making it widely applied in industrial automation production lines.

Features:

Our company's vacuumchuck adopts the "ten-point positioning" principle, eliminating the need for a vacuum pump; air supply from a compressor is sufficient.

Strong suction, automatic pressure maintenance, maintains a certain pressure even in the event of power or air loss. Fast start-up, reaching working status in 4 to 6 seconds. The product is easy to operate, and during the ventilation process, if it is noticed that the tool is not placed correctly, the emergency stop switch can be immediately used.

Applicable to various vertical machining machines, with a wide range of applications; capable of processing flat workpieces regardless of material. Simple and fast operation.

The bottom surface dimensions of machined products should not be less than 120mm * 120mm.

Usage Instructions:

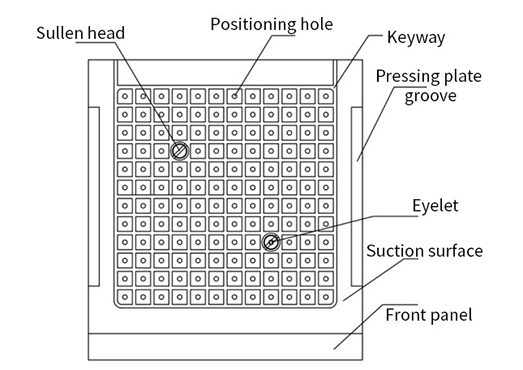

Wipe the bottom of the suction cup clean and place it on the machine table. Secure it by pressing on both sides with the pressure plate groove.

Connect one end of the suction cup's built-in air pipe (8mm) to the suction cup and the other end to the air source in the workshop or equipment.

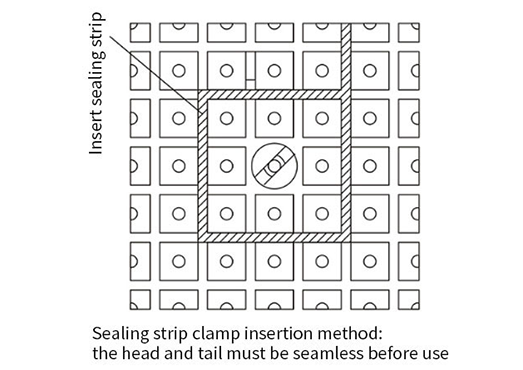

Clamp the sealing element into the key groove of thechuck worktable (below the bottom surface of the already machined workpiece) to enclose the shape of the product (operate with the maximum size, as long as it does not exceed the size of the product).

Place the workpiece on the suction cup table, cover it with the sealing element, gently press it onto the workpiece, and turn on the air source.

Attention:

The vacuumchuck worktable has multiple suction cup holes that can be opened simultaneously, or you can choose one and block the others.

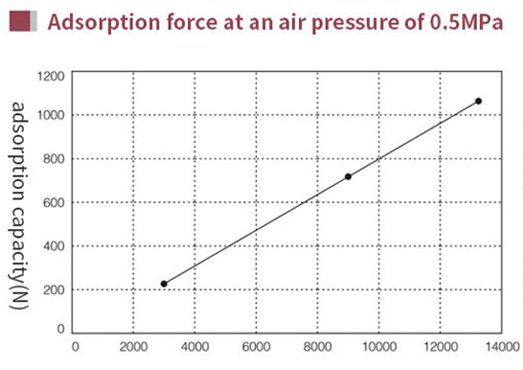

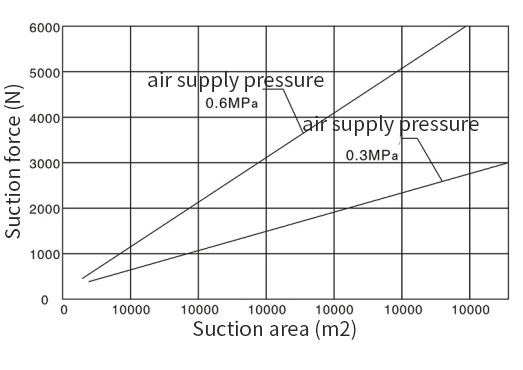

1. Please refer to the chart for suction force, but note that the suction force may vary based on the surface roughness of the adhered surface and the rubber at the junction.

2. The suction force for optional specifications can be determined by vacuum pressure (KPa) multiplied by the adsorption area (mm2).

Specification

| Model | Size (mm) | Groove Size (mm) | Weight (kg) |

| PTK-2040 | 200×400×45 | 3.8×3.2 | 9 |

| PTK-3030 | 300×300×45 | 10 | |

| PTK-3040 | 300×400×45 | 14 | |

| PTK-4040 | 400×400×45 | 18 | |

| PTK-4060 | 400×600×45 | 28 | |

| PTK-4080 | 500×800×45 | 38 | |

| PTK-5050 | 500×500×45 | 28 | |

| PTK-5060 | 500×600×45 | 35 | |

| PTK-5080 | 500×800×45 | 47 |