AlNiCo magnet is the earliest developed permanent magnet material, which is an alloy composed of aluminum, nickel, cobalt, iron, and other trace metal elements. Aluminum nickel cobalt permanent magnet material was successfully developed in the 1930s. At that time, its magnetic properties were the best and its temperature coefficient was small, making it the most widely and widely used in permanent magnet motors. After the 1960s, with the successive emergence of ferrite permanent magnets and rare earth permanent magnets, the application of aluminum nickel cobalt permanent magnets in motors was gradually replaced.

According to different production processes, it can be divided into cast aluminum nickel cobalt (Cast AlNiCo) and sintered aluminum nickel cobalt (Sintered AlNiCo). The product shapes are mostly circular and square. The casting process can be processed and produced into different sizes and shapes; Compared to the casting process, sintered products are limited to small dimensions, and the dimensional tolerance of the produced blanks is better than that of the cast products. The magnetic properties are slightly lower than that of the cast products, but the machinability is better. In permanent magnet materials,

Cast aluminum nickel cobalt permanent magnets have the lowest reversible temperature coefficient and can operate at temperatures up to 550°C.

Application fields: fast mold changing, motors, Electric guitar pickups, microphones, sensors, loudspeakers, Traveling-wave tube, animal husbandry and medical treatment, teaching appliances, etc.

Cast Alnico Magnet Grade

| Grade | Br | Hcb | (BH)max | Tc. | Tw. | aBr | MMPA Equivalent | IEC Equivalent | Germany Standard | |||

| T | kGs | KA/m | kOe | Kj/m3 | MGO | [°C] | [°C] | [%°C] | ||||

| *LN9 | 0.690 | 6.900 | 37 | 0.470 | 9 | 1. 13 | 760 | 500 | -0.03 | Alnico3 | Alnico9/4 | Alnico120 |

| *LN10 | 0.600 | 6.000 | 40 | 0.500 | 10.0 | 1.25 | 760 | 500 | -0.03 | |||

| *LNG12 | 0.720 | 7.200 | 44 | 0.550 | 12.0 | 1.50 | 810 | 500 | -0.03 | Alnico2 | Alnico12/6 | Alnico160 |

| *LNG13 | 0.700 | 7.000 | 48 | 0.600 | 13.0 | 1.63 | 810 | 500 | -0.03 | |||

| LNG16 | 0.800 | 8.000 | 53 | 0.660 | 16.0 | 2.00 | 850 | 500 | -0.02 | Alnico4 | / | / |

| LNG18 | 1.050 | 10.500 | 48 | 0.600 | 30.0 | 3.75 | 850 | 500 | -0.02 | |||

| LNG32 | 1. 180 | 1 1.800 | 44 | 0.550 | 32.0 | 4.00 | 890 | 500 | -0.02 | Alnico5C | / | Alnico500 |

| LNG34 | 1. 180 | 1 1.800 | 44 | 0.550 | 34.0 | 4.25 | 890 | 500 | -0.02 | |||

| LNG37 | 1.200 | 12.000 | 48 | 0.600 | 37.0 | 4.65 | 890 | 500 | -0.02 |

Alnico5

|

Alnico37/5 |

Alnico500

|

| LNG40 | 1.250 | 12.500 | 48 | 0.600 | 40.0 | 5.00 | 890 | 500 | -0.02 | / | ||

| LNG44 | 1.250 | 12.500 | 52 | 0.650 | 44.0 | 5.50 | 890 | 500 | -0.02 | Alnico44/5 | ||

| LNG48 | 1.250 | 12.500 | 52 | 0.650 | 48.0 | 6.00 | 890 | 500 | -0.02 | Alnico5DG | Alnico52/6 | Alnico 600GD |

| LNG52 | 1.300 | 13.000 | 56 | 0.700 | 52.0 | 6.50 | 890 | 500 | -0.02 | |||

| LNG60 | 1.350 | 13.500 | 56 | 0.700 | 60.0 | 7.50 | 890 | 500 | -0.02 | Alnico5~7 | / | Alnico700 |

| LNGT28 | 1.050 | 10.500 | 56 | 0.700 | 28.0 | 3.50 | 860 | 500 | -0.02 | Alnico6 | Alnico26/6 | Alnico400 |

| *LNGT18 | 0.580 | 5.800 | 90 | 1. 130 | 18.0 | 2.20 | 860 | 500 | -0.03 | Alnico7 | Alnico17/9 | Alnico260 |

| LNGT32 | 0.800 | 8.000 | 100 | 1.250 | 32.0 | 4.25 | 860 | 500 | -0.03 |

Alnico8

|

/ | Alnico350 |

| LNGT34 | 0.800 | 8.000 | 104 | 1.300 | 34.0 | 4.25 | 860 | 500 | -0.03 | |||

| LNGT38 | 0.820 | 8.200 | 1 10 | 1.380 | 38.0 | 4.75 | 860 | 500 | -0.03 | Alnico38/11 |

Alnico450

|

|

| LNGT44 | 0.880 | 8.800 | 120 | 1.500 | 44.0 | 5.50 | 860 | 500 | -0.03 | / | ||

| LNGT48 | 0.900 | 9.000 | 120 | 1.500 | 48.0 | 6.00 | 860 | 500 | -0.03 | |||

| LNGT60 | 0.900 | 9.000 | 1 10 | 1.380 | 60.0 | 7.50 | 860 | 500 | -0.03 |

Alnico9

|

Alnico60/11 |

Alnico1500

|

| LNGT72 | 1.050 | 10.50 | 1 12 | 1.410 | 72.0 | 9.00 | 860 | 500 | -0.03 | / | ||

| LNGT82 | 1. 100 | 1 1.000 | 120 | 1.500 | 82.0 | 10.25 | 860 | 500 | -0.03 | |||

| LNGT88 | 1. 100 | 1 1.000 | 120 | 1.500 | 88.0 | 1 1.00 | 860 | 500 | -0.03 | / | ||

| LNGT92 | 1. 120 | 1 1.200 | 120 | 1.500 | 92.0 | 1 1.50 | 860 | 500 | -0.03 |

|

|

|

| LNGT36J | 0.700 | 7.000 | 140 | 1.750 | 36.0 | 4.50 | 860 | 500 | -0.03 | Alnico8HC | Alnico36/15 | Alnico450 |

Note:* means Isotropy.

Unit conversion:

Note: SI unit and CGS Conversion of units formula:

1 T= 1000mT 1 kGs= 1000Gs

1 T= 10 kGs,

1 kA/m=4π Oe,

1 kJ/m³=4π×10¯ 2 MGOe,

Physical Properties of Cast Alnico Magnets

| Curie Temperature | 760-890°C |

| Max.Operating Temperature | 450-550°C |

| Resistivity | 47-54μOhm.cm |

| Vickers Hardness | 520-630Hv |

| Density | 6.9-7.3g/cm³ |

| Relative Recoil Permeability | 1.7-4.7 μrec |

| Saturation Field Strength | 2.7-6.3kOe/215-500kA/m |

| Temperature Coefficient of Remanence(Br) | -0.025~-0.02%/C |

| Temperature Coefficient of Remanence(iHc) | +0.01~0.03%/C |

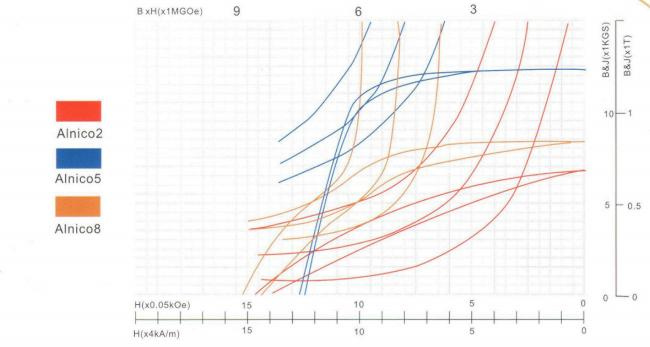

Typical Demagnetizing Curves of Cast Alnico